Prototek

@prototek

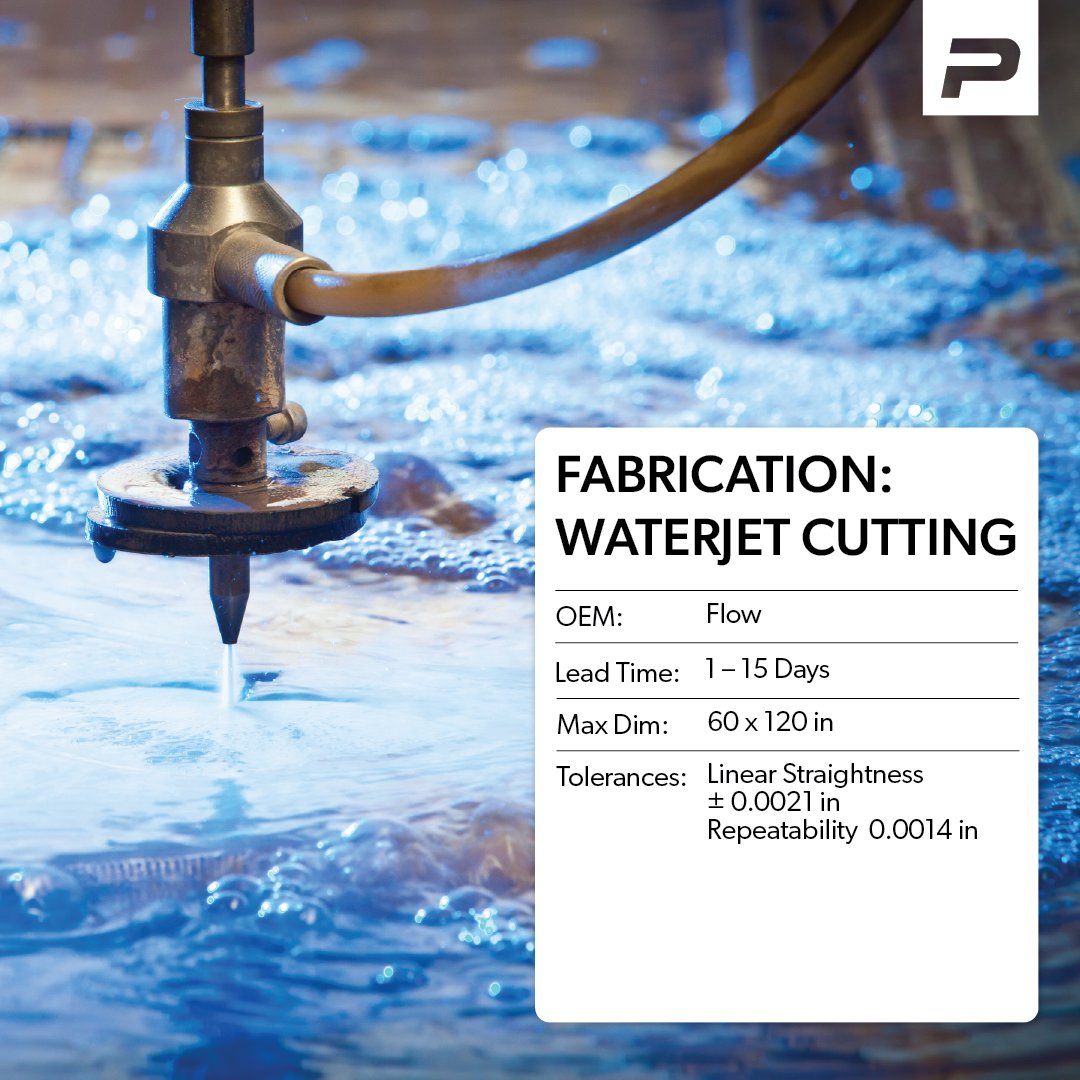

Sheet Metal Fabrication, CNC & Machining Prototyping & Parts. Quote in 24hrs. Challenging parts & deadlines our specialty. We turn out jobs others turn away!

ID: 79419675

https://www.prototek.com/ 03-10-2009 09:34:52

3,3K Tweet

244 Followers

91 Following