kanoumould

@kanoumould

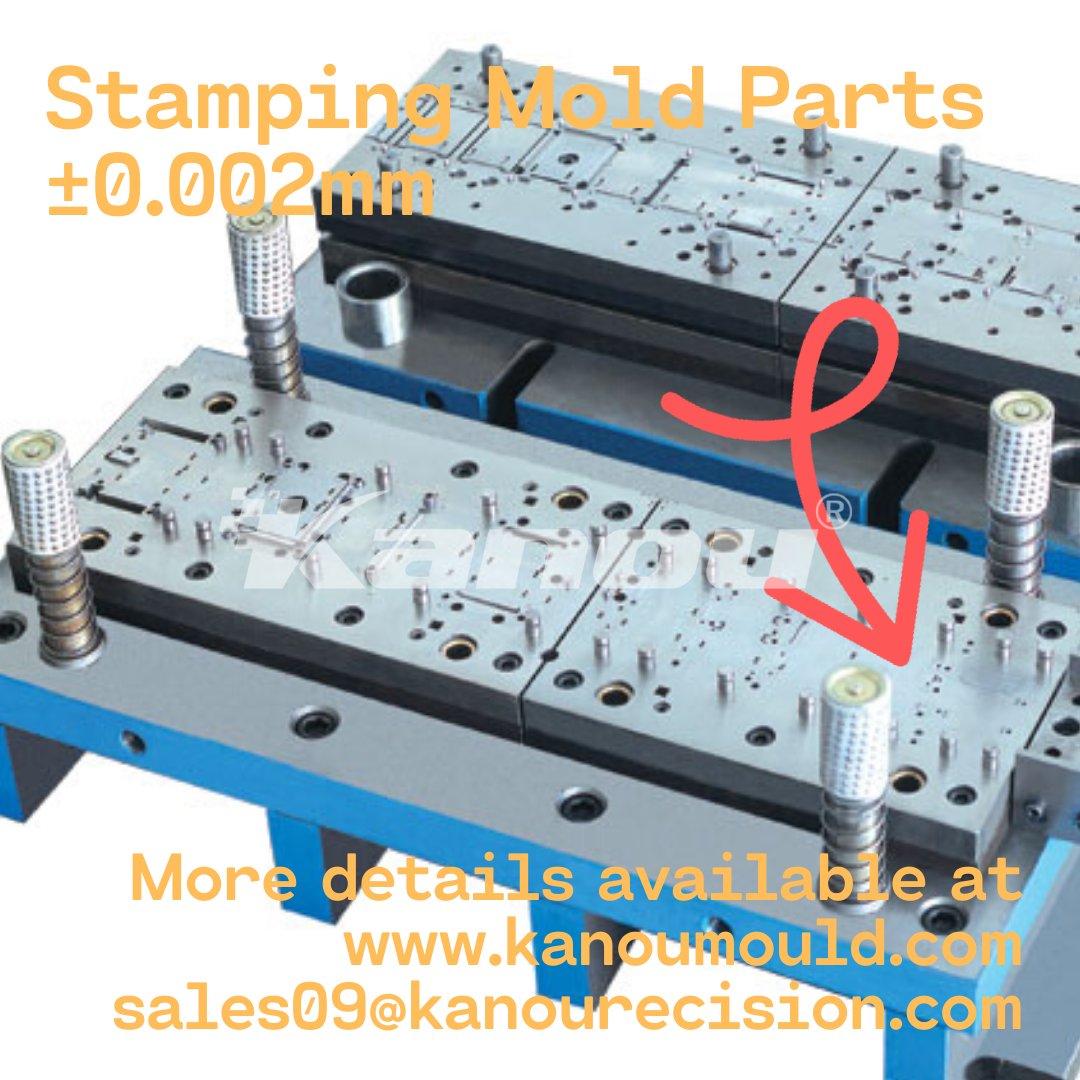

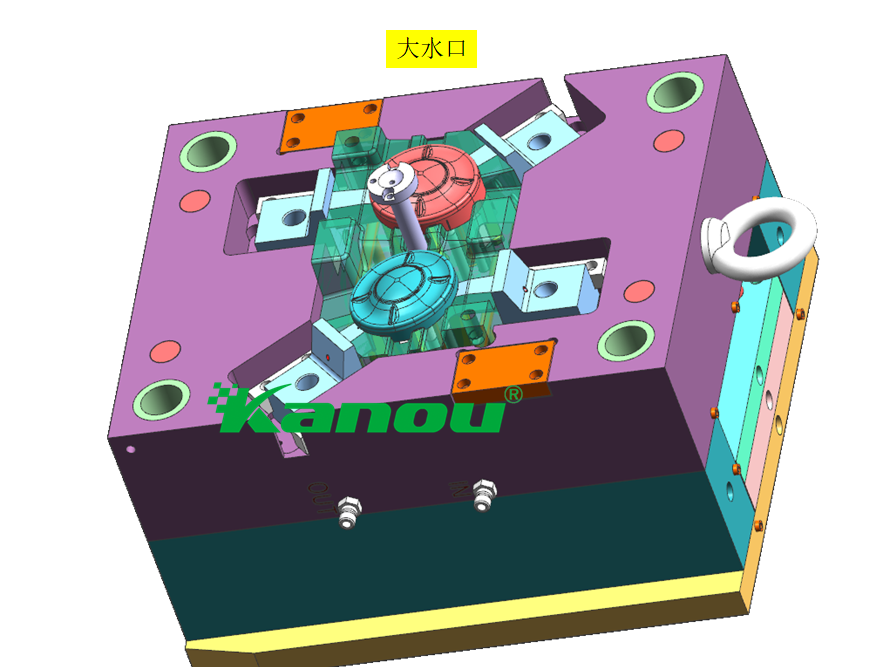

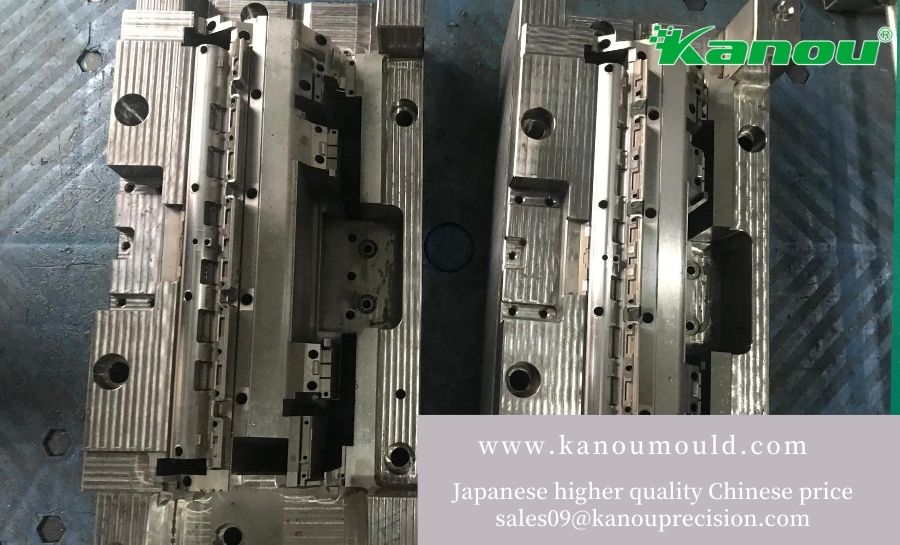

Kanou Precision Auto Industry (Dongguan) Co., LTD is a professional plastic injection manufacture and mold parts maker.

ID: 1185109978320920577

18-10-2019 08:27:04

67 Tweet

14 Followers

7 Following

Processing of Plastic Mold Parts of E-cigarette Shell #kanoumould #die #mold #plastic #injectionmoulding [email protected]