PRINTING PERSPECTIVE

@printperspec

Hey, I am Gerard and I specialize in creating videos that focus on exploring the performance of 3D printing-related designs, concepts, settings, and products.

ID: 925448826776903686

https://www.youtube.com/@PrintingPerspective 31-10-2017 19:46:09

502 Tweet

437 Followers

88 Following

In a new video, I am checking out quite a crazy INDUCTIVE hotend - INo Trident by plasmics_3d youtu.be/XphpaHd8Q9s Are inductions hotends the future or just a gimmick? 🤨

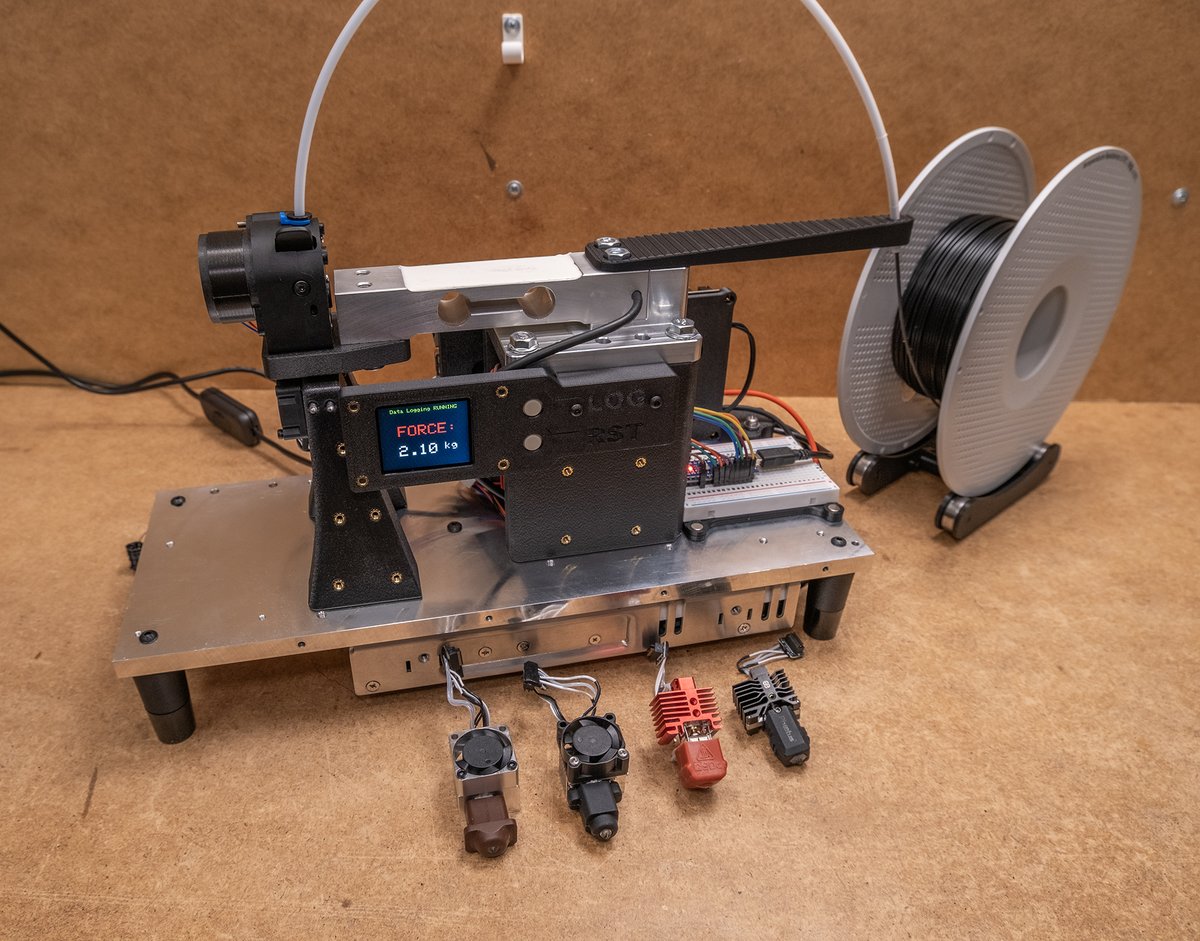

Does layer adhesion correlate with the required extrusion force? 🧐 I have some nice and interesting hotends to test: Slice Engineering Mako™ Microswiss FlowTech™ Phaetus3D Conch V6 Swiss3Dc Starlex DHB 🙃

![PRINTING PERSPECTIVE (@printperspec) on Twitter photo [NEW VIDEO] youtu.be/2llbJXqTmow

In this video, I explored what happens if you print at a narrower extrusion width than the nozzle size. [NEW VIDEO] youtu.be/2llbJXqTmow

In this video, I explored what happens if you print at a narrower extrusion width than the nozzle size.](https://pbs.twimg.com/media/GnleHdGW0AA7Pai.jpg)