Inductotherm Corp.

@InductothermUSA

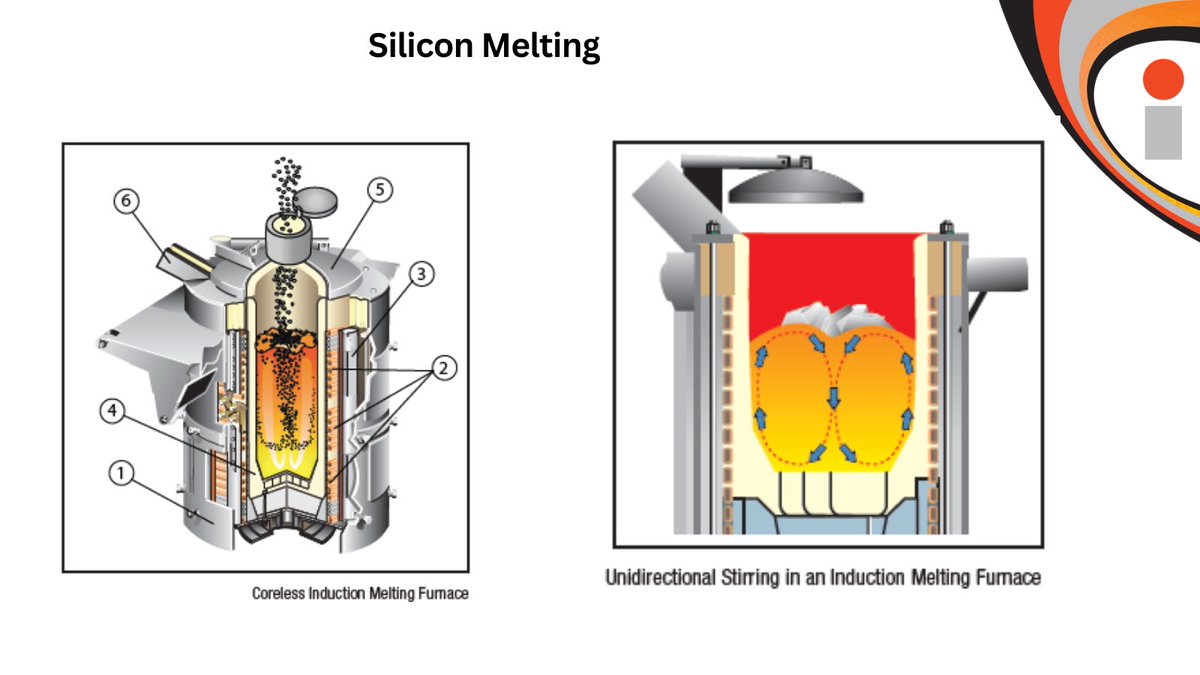

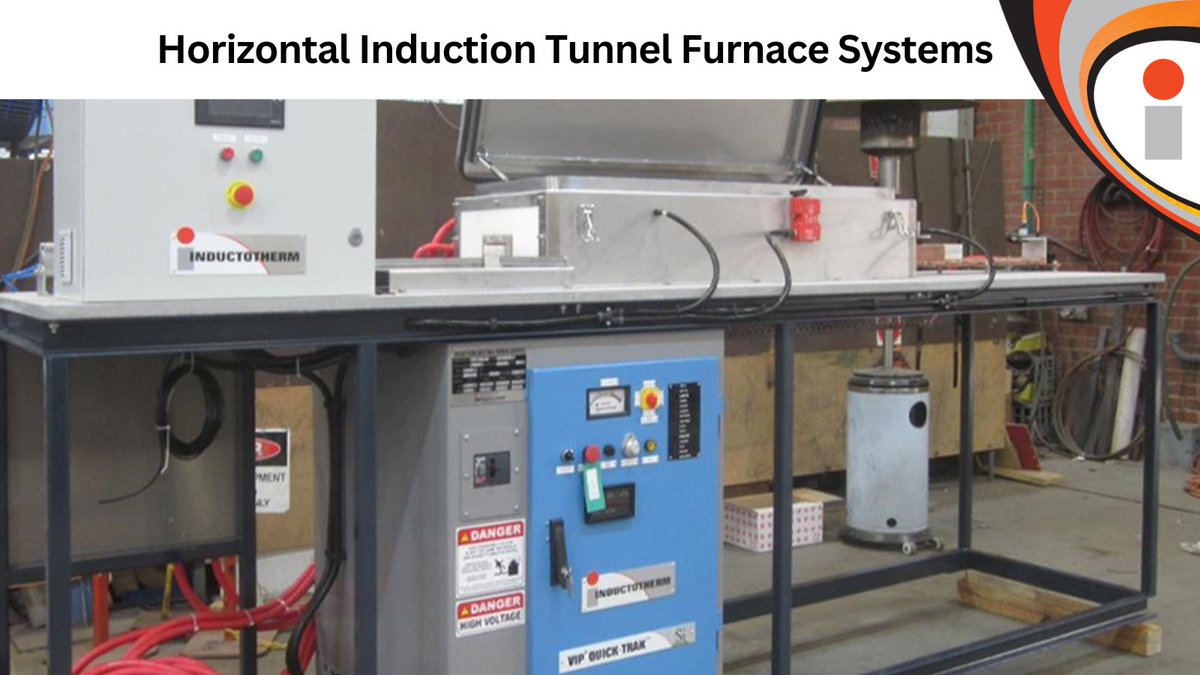

We manufacture Induction furnaces for foundries & melt shops looking for the most efficient, reliable & advanced systems for melting, heating & pouring metals.

ID:857974968419856384

http://www.inductotherm.com 28-04-2017 15:09:07

2,2K Tweets

758 Followers

272 Following

The IRIS™ System provides valuable data that can be used for analyzing the lining wear. Foundries and melt shops can now scan furnace linings, monitor lining wear and store key data in real time using the IRIS™ System.

inductotherm.com/products/iris-…

#foundry #induction #metalcasting

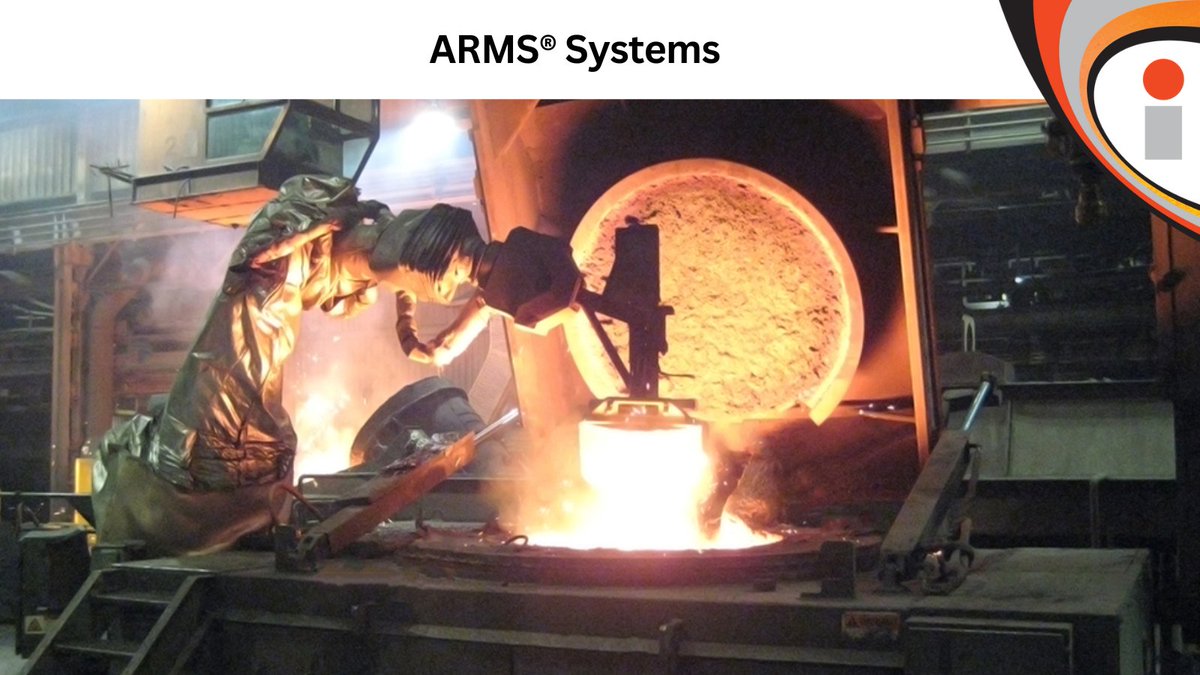

The Inductotherm ARMS® System is a patented concept that uses a robot to perform the hazardous operations that would otherwise be handled by a furnace operator, allowing the melt deck worker to be relocated to the control room.

Click: inductotherm.com/products/arms-…

#Induction

Pressure Pour Automated Pouring Systems are ideal for applications that require volume flexibility at the mold line by holding molten metal at an exact temperature while delivering precise pouring control.

Click: inductotherm.com/products/press…

#engineering #metalcasting #foundry

Open Evaporative Cooling Systems allow for the possibility of dual spray pumps & heat exchangers and can be used for both de-ionized and non-deionized systems.

With these systems multiple closed systems can be cooled using a single tower.

inductotherm.com/products/open-…

#coolingsystem

Discover how Inductotherm systems help our customers over at Lodge Cast Iron keep their legacy of more than a century still going strong. 🍳💪

inductotherm.com/customer-porta…

#castiron #manufacturing

Inductotherm Corp. was incorporated on April 13th and this date has since become known as Inductotherm Day. Each year we take a moment to #celebrate our founder, Henry Rowan, and appreciate the strong foundation that he created. #founder #inductotherm #manufacturing #newjersey

We are thrilled to have our very own Ed Chmielecki on-site at the AFS Texas Regional, eagerly anticipating the opportunity to reconnect with familiar faces and forge new connections. #AFSConference #Arlington #Texas #InductionMachinery #Foundry #Foundries #networking

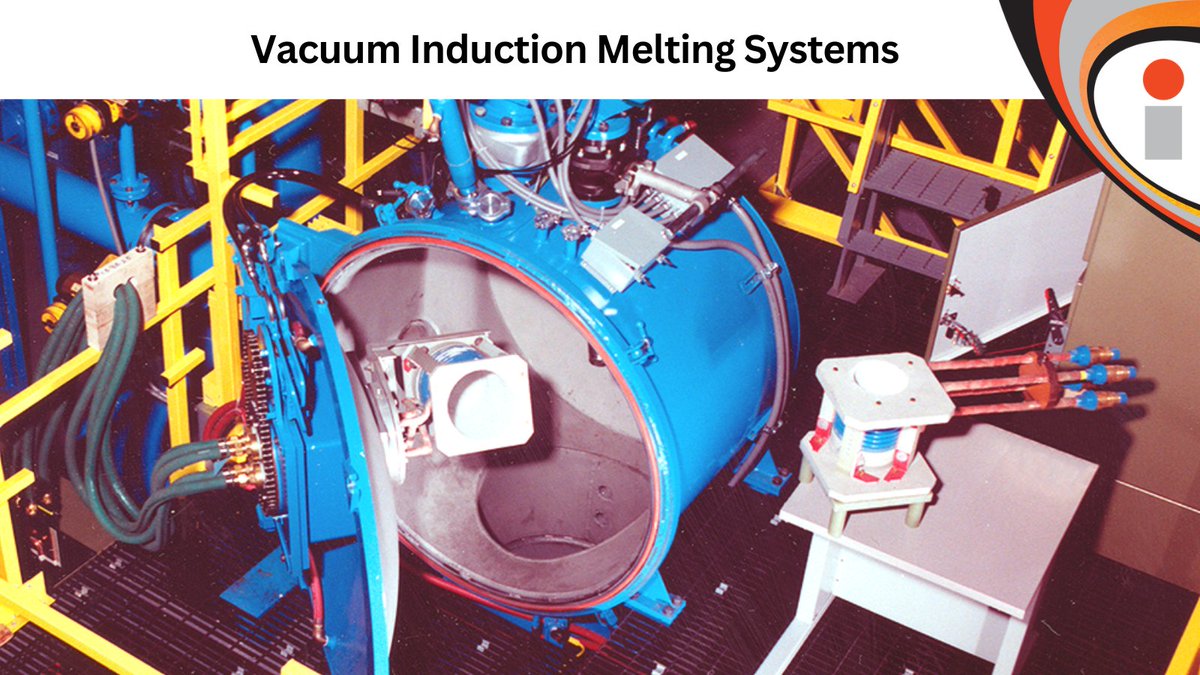

Equipment strategically engineered for virtually every steel melting operation; including foundries, investment casting shops, mini-mills, and vacuum melting operations.

inductotherm.com/applications/s…

#Steel #induction #engineering

Power two or more furnaces simultaneously for greater production with VIP® Multi-Output™ Power Supplies.

These units offer great metal quality and superior operational flexibility with lower operating costs.

inductotherm.com/products/vip-m…

#powersupply #induction #superior

The Inductotherm ARMS® System is a patented concept that uses a robot to perform the hazardous operations that would otherwise be handled by a furnace operator, allowing the melt deck worker to be relocated to the control room.

Click: inductotherm.com/products/arms-…

#Induction

With more induction melting systems operating worldwide than any other manufacturer, Inductotherm’s furnace and power supply cooling systems are proven to be suitable for virtually every climate type and temperature extreme.

inductotherm.com/product_catego…

#reduceenergycosts #Induction