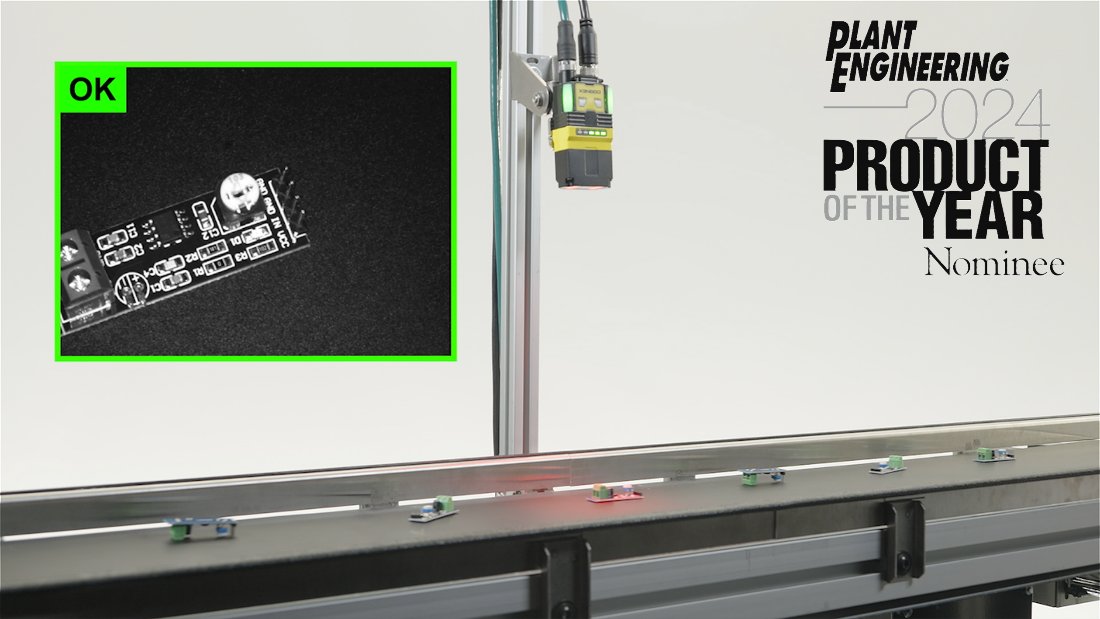

Cognex

@cognex_corp

Companies around the world rely on Cognex machine vision and industrial ID to optimize quality, drive down manufacturing costs, and control traceability.

ID: 16687469

http://www.cognex.com 10-10-2008 19:06:40

1,1K Tweet

4,4K Followers

237 Following